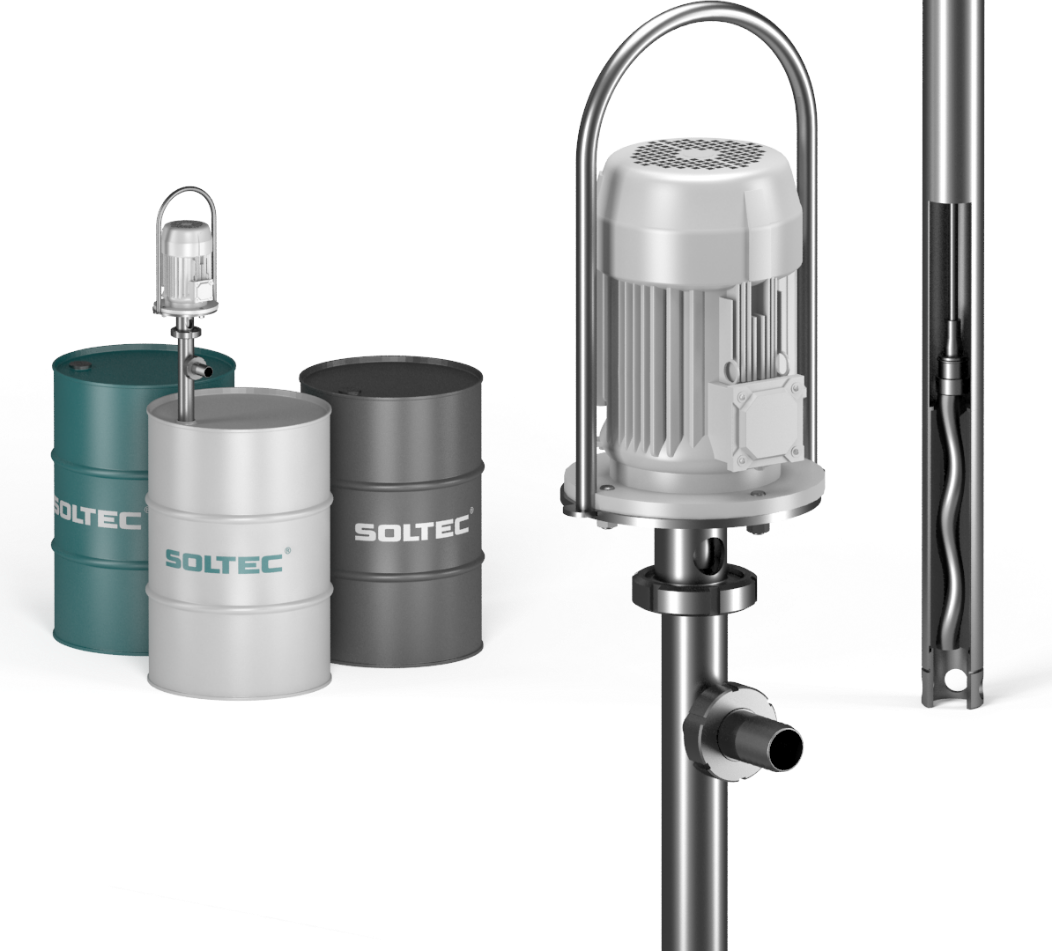

BARREL PUMPS

SOLTEC®

SOLTEC® universal range of BARREL pumps for various liquids.

SOLTEC © 2025 All rights reserved.